IONIQ 20 – 洩漏測試儀

電池測試

ATEQ 在生產線品質控制測試儀這一成熟概念的基礎上,針對大量生產塑膠零件的特殊要求,開發了一種新型洩漏測試儀。儀器用於檢測局部成型故障、膜厚度不足、穿孔等。事實證明,該儀器在測試袋裝電池芯方面也很有效。

IONIQ 以放電電流測量為基礎,能夠檢測出 10 微米以下的缺陷。

IONIQ 20 : 應用

電池袋電池、塑膠瓶蓋、塑膠包裝..

IONIQ 20 : 測試原理

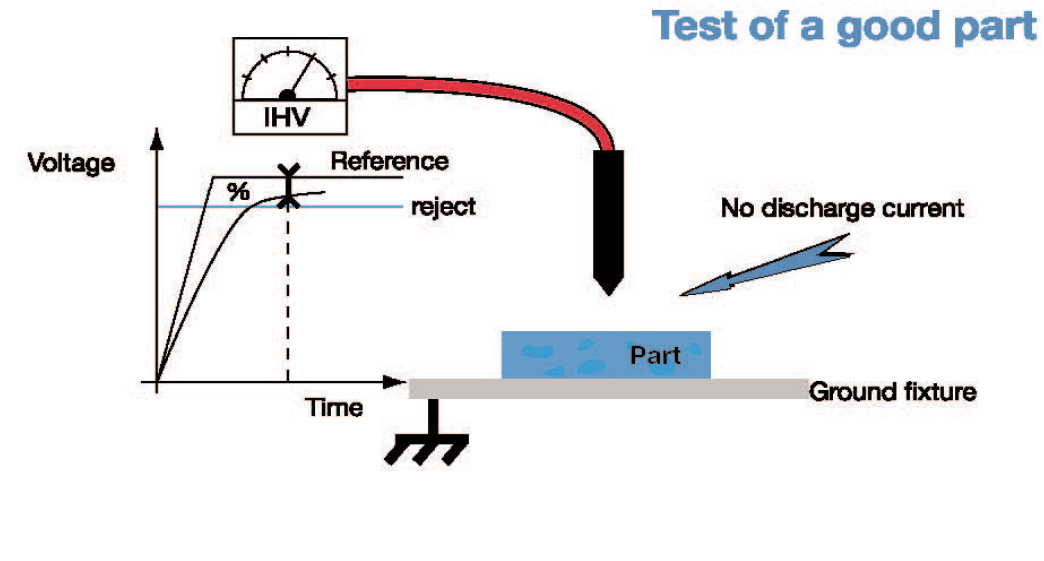

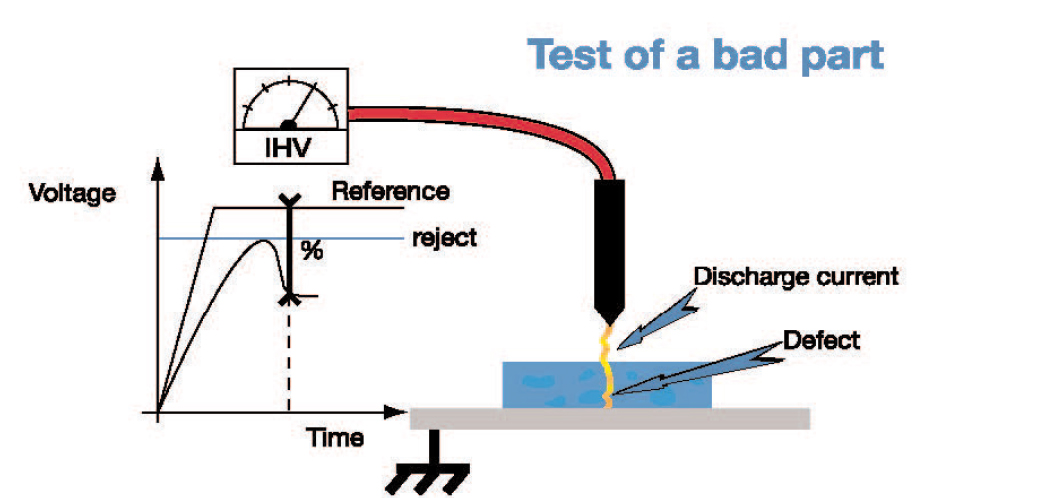

• The IONIQ measures the current flowing between a patented charged probe and a ground plate placed under the part to be tested.

• The IONIQ uses the % of the nominal voltage (which reflects the discharge current), measured on the part as PASS/FAIL level.

• In a PASS situation (fig 1) : No hole, no weak part, the IONIQ measures a high %. The measured voltage and the nominal voltage are virtually equal. The result is above the reject level, the part has passed the test.

• In a FAIL situation (fig 2) : The IONIQ measures a low %. The measured voltage is significantly below the nominal voltage. The result is below the reject level, the part has failed the test.

• Test limitations: short probe-part-plate distance, electrical insulation from environment.

IONIQ 20 : 特點

• Integrated ionising high voltage generator (5 to 27.3 kV)

• Reject levels as % of nominal voltage (0 to 100%)

• Monitoring and protection of high voltage generator

• Limitation of the current rating

• Speed: Minimum cycle time 0.6s

• I/O’s for instrument control and results

• 32 programs

• Remote control allows the test module to be closed to the test part

• And: Language selection, customization of test …

IONIQ 20 : 技術規格

IONIQ 20 : 產品手冊

有關 IONIQ 20 的詳細信息,包括功能、規格等。

IONIQ20 : 技術

A high voltage loaded sharp end is applied next to an earth connected base and in between lays the plastic part we test. Should a hole exist in the part, ions will start moving from the earth to the sharp end. This will result in a loss of power and be translated into a leak.

While this method does not quantify the leak rate in terms of cc/min for example, it is the fastest ever invented to detect a leak in a go / no go process.

We have achieved cycle times of less than 7/10 of a second.

洩漏範圍:取決於孔的大小和零件的材料

精度:取決於孔的大小和零件的材料